What is DMLS 3D printing?

DMLS stands for Direct Metal Laser Sintering. You could say it is like a cousin of the SLS 3D printing method, since both use laser sintering to obtain the desired results. The main difference is that DMLS 3D printing is a process that is applied on metal powder instead of plastic powder, so it belongs to the group of metal 3D printing methods.

This technology is one of the few available to create a metal part directly from the 3D CAD model. Similar to what happens in SLS, in DMLS 3D printing, the metal powder is sintered by pointing a laser that transforms the powder into a solid metal piece.

Compared to other 3D printing technologies, DMLS 3D printing could be considered new. The most popular technologies like FDM and SLA were first developed in the 80s, whereas DMLS had its first patent filed in the 90s. Let’s take a look at the details of the DMLS operating principle.

How does DMLS 3D printing work?

Generally speaking, DMLS 3D printing follows the same operating principle as the majority of 3D printing technologies, which can be summarized in three steps: design, slice and print by layers. However, there are some details that are specific for this technology and the type of material used.

Here are the printing steps in detail:

1.A container, usually called the hopper is filled with the metal powder that will be used, with aluminum, copper and titanium powders commonly used.

2.The powder is preheated inside the hopper until it reaches a temperature near the required for sintering the specific material in order to help the laser achieve quality results more easily.

3.As metals are more susceptible to react with the environment than plastics, an inert gas is used is used to protect the material along the process.

4.Inside the container, a build tray is covered with a thin layer of the metal powder by means of a roller.

5.The laser selectively sinters the preheated powder by following the route indicated by the software of the printer until it creates the first layer of the model. Sometimes, support structures are required, and these are printed before the geometry of the layer.

6.Both steps 4 and 5 repeat until the metal piece is completely printed.

7.When the piece is completed, both the piece and the printer are still hot, so a cooling time is required before the piece can be removed.

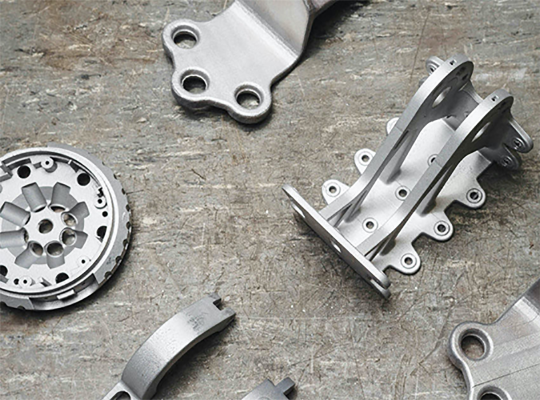

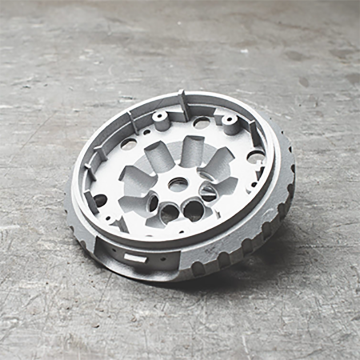

8.When everything has cooled down, the piece is removed from the printer for post processing. The first and mandatory post processing step is to clean the piece by removing support structures and any powder remaining on the surface. Other post processing steps may include any treatment that may be required, as metal printed parts can be treated as any other metal part produced with any other manufacturing process.

Why would I use DMLS 3D printing?

It is true that DMLS 3D printing may be pricey, as both machines and materials are among the most expensive ones in the 3D printing market. This fact, together with the limited speed of the process when compared to others, may guide anyone away from this technology. However, there is a group of benefits that could make DMLS the best option for your specific application. Here are the most important benefits you can get:

Direct production: Metal parts are produced directly in one single printer. Pure metal and alloys are printed in one single process while keeping the properties of the material. If required, mixed materials can be printed, for example, nylon with aluminum powder at the same time.

Wide range of materials: Apart from the common materials mentioned above, there are many options available in the market. Metals like steels and stainless steels, nickel alloys and even precious metals can be used in DMLS 3D printing.

Recycling: The remaining metal powder can be recycled for use in a future print.

Strength and functionality: All parts printed with DMLS are as strong and functional as metal parts coming from other manufacturing processes. Some of them may even be compared with castings, and the mechanical properties are not affected by printing directions as it may happen with other technologies like FDM 3D printing.

As you can see, the benefits justify the cost in some applications, and with future developments we can expect prices to go down. Anyways, if you are still dealing with some doubts, the recommendation is to consult with an expert to avoid undesired failures and reduce costs related to repeated work in trial an error.