What is HPMJF 3D printing?

MJF stands for Multi Jet Fusion, a very modern 3D printing technology developed by the famous brand Hewlett Packard, hence the full name HPMJF 3D printing.

Similar to SLS 3D printing, HPMJF 3D printing belongs to the category of industrial powder bed fusion, where plastic powders are fused to build solid plastic parts, mainly from thermoplastic polymers like nylon. The main difference they have lays on the source of heat to fuse the material.

While in SLS 3D printing the powder is sintered by means of a laser, in HPMJF 3D printing the material is processed with a fusing and detailing agent, sometimes called “ink”, which stimulates the absorption of infrared light.

Let’s see this process in more detail.

How does HPMJF 3D printing work?

As it happens with any other additive manufacturing technology, the process to build a prototype or fully functional piece with HPMJF 3D printing starts with the 3D CAD model. Also, the model is loaded into the software of the printer which creates the layers that will be printed. Then, the actual printing process begins by following these steps:

1.The build platform is covered with a thin layer of the plastic powder. This layer is preheated until a temperature near to the sintering temperature is achieved. That way the material is prepared for fusing.

2.Nozzles similar to those found in 2D desktop printers are passed over the thin layer of powder while jetting both fusing and detailing agents according to the information obtained from the CAD model.

3.Lamps with infrared light are moved over the layer of powder and the “ink” absorbs that energy, so the jetted powder is fused while the rest stays unchanged. The detailing agent is left on the outer surface and edges of the layer being printed as this will help improve the surface quality and resolution of the print.

4.The previous 3 steps are repeated until the whole piece is finished.

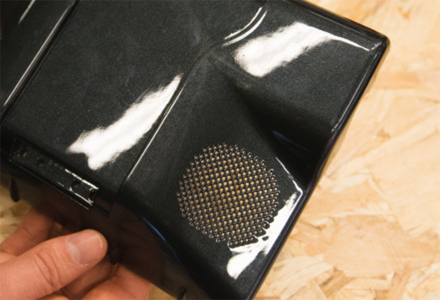

5.Similar to the pieces printed with SLS technologies, pieces printed with this technology require cooling time and the removal of any remaining powder by cleaning the surface.

It is important to highlight that, compared to SLS 3D printing, HPMJF 3D printing requires shorter cooling times and post processing can be faster. The faster post-processing is achieved by means of a dedicated station offered by HP, which also claims that 80% to 85% of the unused powder can be recovered in this station for future reuse.

What are the main benefits of HPMJF 3D printing?

By looking at the way the technology works and the comparisons made so far with SLS 3D printing, it is obvious that HP’s technology offers an improvement of the benefits that can be obtained with SLS.

More specifically, the main benefits of HPMJF 3D printing include:

1.High precision, with material jetted at 1200 DPI.

2.No support structures required, which reduces printing time and post-processing time.

3.Low layer and wall thickness can be achieved.

4.Short cooling times and great recyclability which results in short lead times and increased productivity.

Final thoughts

HPMJF 3D printing is very similar to SLS 3D printing, with both technologies achieving high-quality functional parts with smooth surface finishes. However, HPMJF can be a better option if you need a small number of parts in a short time. On the other hand, if you need special materials, you may need to go with SLS, as it has a wider offer.

Anyways, if you are not sure, the recommendation is to consult with an expert to avoid undesired failures and reduce costs related to repeated work in trial an error.